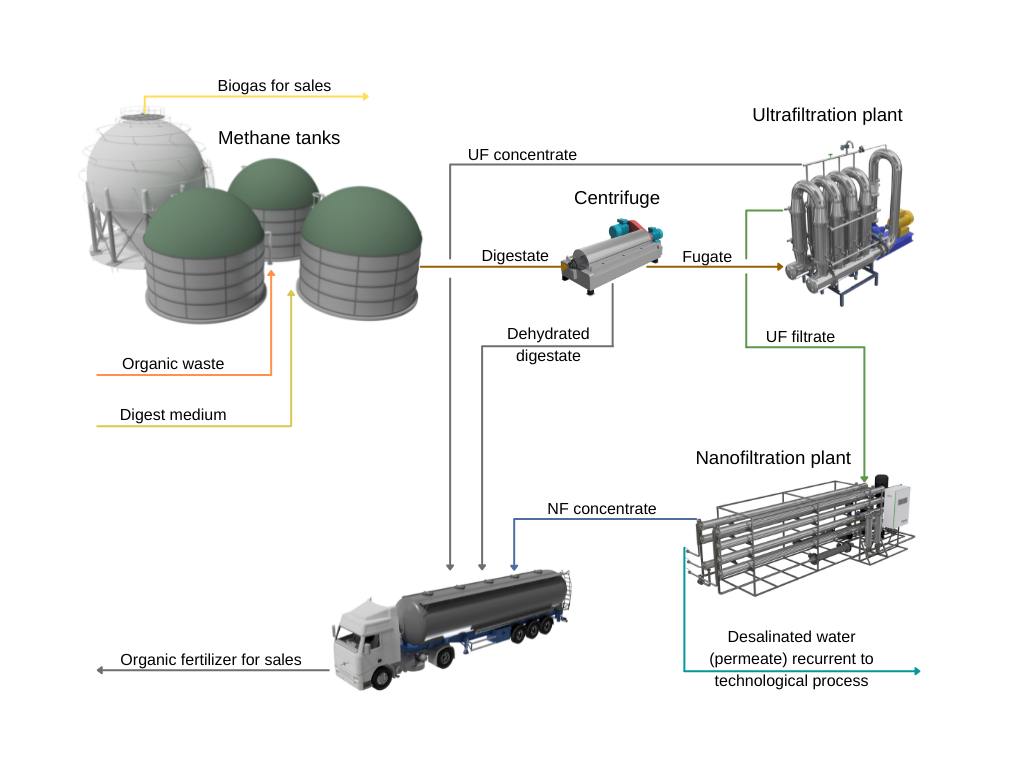

ORGANIKA ENGINEERING OFFERS NEOTERIC TECHNOLOGIES OF FILTRATION OF DIGESTATE (WASTE) AFTER METHANE FERMENTATION

After methane fermentation, digestate is pre-separated, where a solid (31-35% DM*) suspended fraction is separated. The liquid fraction - fugate (1-8% DM) is fed to the ultrafiltration separation and concentration on ceramic membranes. The concentration of DM (dry matter) depends on the quality of raw materials that are supplied for methane fermentation.

UF permeate (filtrate) (0.5-2.0% DM) enters the reactor tank, where the pH of the mixture is corrected.

Then the mixture is fed to a nanofiltration plant (NF), in which it is divided into NF concentrate and permeate (filtrate) on polymer membranes.

At the request of the customer, the clarified NF permeate can be finally cleaned on a reverse osmosis (RO) system. The prepared, filtered water is returned to recycling production. UF (10-20% DM*) and NF (8-12% DM) concentrates are collected and taken away.