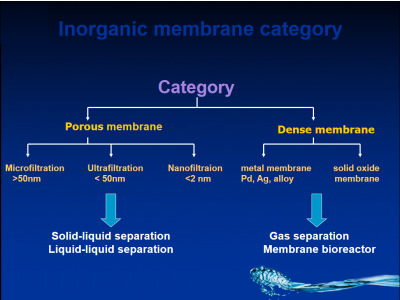

ORGANIKA ENGINEERING provides services in the area of implementation of water treatment technologies, concentration of processing medium with the help of baromembrane filtration methods. Microfiltration, ultrafiltration, nanofiltration and reverse osmosis – these are kinds of baromembrane processes under which the flow of water or processing solution with certain pressure is pressed through membrane. Through these features baromembrane technologies are widely used in different fields of manufacturing industries: processing, food, medical industries and others.

The group of baromembrane methods includes:

Reverse osmosis:(size of pores 1 – 15 Å, operating pressure 0.5 – 8 MPa) is applied for water desalination, keeps hold of practically all ions (92-99%), and if applied with two-stage system it can hold up to 99,9%

Nanofiltration(size of pores 10 – 70 Å, operating pressure 0.5 – 8 MPa) is applied to separate coloring agents, pesticides, herbicides, sucrose, some soluble salts, organic matters, viruses etc.

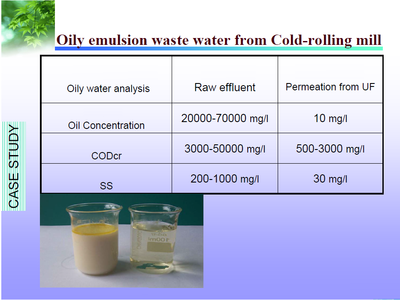

Ultrafiltration (size of pores 30 – 1000 Å, operating pressure 0.2 – 1 MPa) is applied for some colloids (silicium for example), viruses (incl. poliomyelitis), coal soot, milk fractions etc.

Microfiltration(size of pores 500 – 20000 Å, operating pressure 0.01 – 0.2 MPa) is applied to separate some viruses and bacteria, micropigments, dust of active carbon, asbestos, coloring agents, fractions of oil-in-water emulsions etc. The bigger pores in membrane – the better understanding of membrane filtration process – the more it physically nears so-called mechanical filtration.