Waste water (effluents), which is the product of technological activities of many grain and bean processing enterprises, dairy and meat processing enterprises, and meat and bone meal production, are divided into: biological, chemical, and thermal.

We offer to configure a wastewater treatment system for:

- food industry,

- enterprises with effluents of organic origin.

Operation of a pilot line for processing wastewater from meat factory.

Operation of a pilot line for processing fugate of grain distillery dregs.

Currently, the traditional methods of treatment of industrial wastewater and effluents, depending on their contamination, are biological, chemical and physical treatment.

Biological treatment involves cleaning using two types of bacteria - aerobic and anaerobic. The main disadvantage of the technology is the presence of large areas for treatment facilities, and unpleasant smell in their neighborhood.

Chemical treatment is based on the removal of suspended and soluble substances using chemical reagents that interact with each other to form a precipitate or foam. The disadvantage of this method is the addition of a reagent, changes in the chemical composition of wastewater, the need to separate sediment, foam and their disposal, bulkiness, and complexity of the technology.

Physical treatment is based on the physical effects of influence on effluents. It allows you to clean industrial effluents from almost all contaminants.

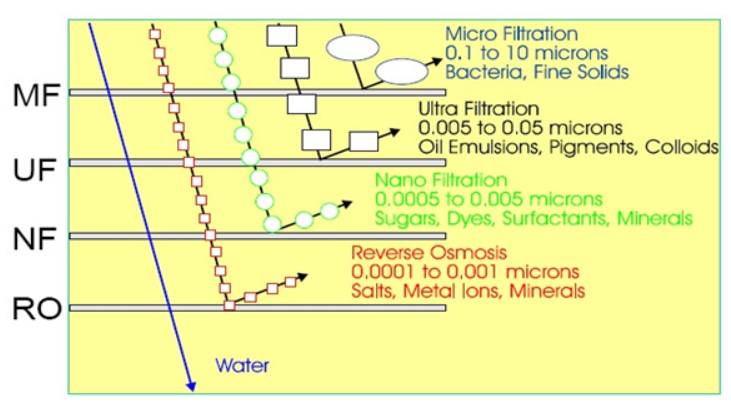

In addition to existing, and to some extent, outdated methods of treatment, and at the same time preparation of water for production processes: artesian, surface water (ponds, rivers, seas), as well as water returned by recycling, that is, cleaning its own wastewater Organika engineering offers microfiltration, ultrafiltration and nanofiltration - these are types of baromembrane processes in which the flow of water or process solution under certain pressure and conditions, due to the difference in the molecular structure, is forced through the membrane. As a result of this treatment, depending on the customer's request, wastewater can be cleaned up to the level of distilled water.

DEGREES OF FILTRATION

| MF |

Microfiltration from 0.1 to 10 microns Bacteria, small solid particles |

| UF |

Ultrafiltration 0.005 to 0.05 microns Oil emulsions, pigments, colloidal particles |

| NF |

Nanofiltration from 0.0005 to 0.005 microns Sugar, colorants, surfactants, minerals |

| RO |

Reverse osmosis from 0.0001 to 0.001 microns Salts, metal ions, minerals |

|

Water |

ADVANTAGES OF THE BAROMEMBRANE TREATMENT METHOD

Advantages of this treatment method:

- Compact, easy to maintain;

- The process is fully automated;

- Treatment is carried out without adding additional reagents;

- High efficiency of cleaning, at the request of the customer - to distilled water;

- Relatively low power consumption.

CHARACTERISTICS OF WASTE WATER OF FOOD INDUSTRY ENTERPRISES

| Enterprises | Suspended substances, mg/l | COD, mg/l | BOD5, mgO2/l |

| Sugar production | 1200-2600 | 4900 | 1400 - 3600 |

| Yeast production | 1900 | 1800 | 1500 |

| Breweries | 2650 | 2000 - 6000 | 1500 - 4000 |

| Alcohol production (distillery dreg) | 32 000 - 45 000 | 20000 - 48000 | 15500 - 29900 |

| Production of low-alcohol beverages | - | 1760 | 1200 |

| Starch processing (potato) plants | 600 - 4700 | 100 - 2520 | 300 - 1300 |

| Dairy enterprises | 350-600 | 1200 - 3000 | 500 - 2000 |

| Cheese factories | 400 -750 | 51200 | 40 000 |

| Manufacture of casein | 300 - 500 | 52 587 | 41 083 |

| Biomycin filtrate | - | 22 200 | 19 900 |

| Fruit and vegetable production | 20 - 1800 | 440 - 2690 | 350 - 2175 |

| Meat processing plants | 410 - 12000 | 1800 - 12500 | 650 - 5100 |

| Confectionery (average effluent) enterprise | 1220 - 1790 | 6060 | 2190 |

| Ice cream production | 8000 | 6000 | 4000 |

Since food processing plants are engaged in processing various types of raw materials, the contamination of the resulting industrial wastewater may be different. Therefore, the selection of equipment and development of a technological scheme for industrial wastewater treatment are individual for each specific case.

Please leave your contact details and our specialist will contact you to clarify the details and calculate the cost.