Today, the location on the map is not so important. The presence of mineral deposits in the country is less valuable than the presence of specialists who implement the latest technolo-gies. Especially when they are intended to save from an environmental disaster, which is caused by industrial pollution of water, soil, and total dehydration.

This is the focus of developers' innovations in LLC "ORGANIKA". They managed to do almost the impossible: clean industrial wastewater to the state of water, which can be regenerated again in the technological cycle or safely dumped into the ecosphere. And use concentrated reagents for animal feed or land fertilizers!

At this very moment ORGANIKA embodies this in metal, processes, and IT-algorithms. The result is impressive.

Over the past 20 years, the Ukrainian company has been developing solutions for wastewater treatment based on innovative membrane technologies for separation of components at the molecular level. These technologies are used in NASA projects to maintain life on space stations.

Industrial effluents are concentrated and cleaned water is returned to the production cycle

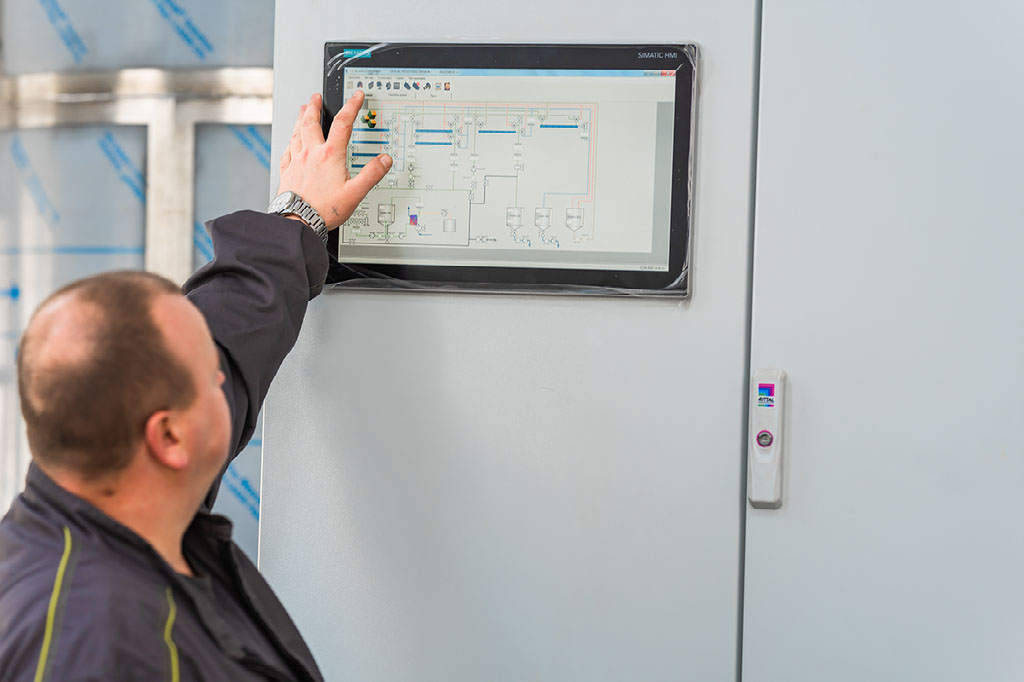

The biggest plus – the complex saves water. About 90% of the water will return back to the production cycle. Without dirt and unpleasant odors. The work is automated; everything is controlled by its own software. Heavy physical labor is excluded, and the staff only performs preventive work.

In enterprises that already use this system, they have no idea how they managed without it before. This is already working in the EU so ORGANIKA is eagerly waiting for new customers. Sewage treatment is critically needed in every country, while there is still something to save.

Sewage treatment is critically needed in every country, while there is still something to save

Wastewater treatment technology is suitable for ethanol, starch, fat and oil, meat processing, dairy industries, etc. The equipment is created based on the characteristics of wastewater for any scale of production.

Similar solutions have been implemented in Ukraine for cleaning and concentrating process media. Engineering projects of ORGANIKA are successful in Europe, have a significant economic impact and protect the environment. The company is currently working on a technological project to build a new ethanol plant in the EU.

The indicators are inspiring.

The algorithm for working with customers is clear. After studying the request, the process envi-ronment is analyzed. Next, engineers will visit the facility with pilot equipment, demonstrate the quality of work, and develop the TCO (Technical Commercial Offer).

Now the "treatment equipment line" is being created in Ukraine.

The work is automated, everything is controlled by its own software. The main process equipment was created by ORGANIKA's projecting engineers.

The complex provides backup operation and safe service, without stopping processes.

The idea that brings the metal to life

The path to solving the problem of industrial effluents lasted for many years. Back in the 2000s, ORGANIKA began searching for effective ways to dispose of industrial waste, in order to protect nature from pollution. Soon we added a task - to reduce the use of mineral resources.

The first engineering project was implemented 12 years ago in the European Union. Since then, we have won tenders from even major corporations from the United States, Germany, Turkey and Austria.

Vasyl Olshakovskyy and Orest Pomozybida - young ORGANIKA's engineers. They make the future.

Unfortunately, the components certified according to international standards are not generally produced in Ukraine. So for "Treatment equipment line" they were collected over the entire Eurasian continent, from Germany to South Korea. The crucial criterion is the quality certificate.

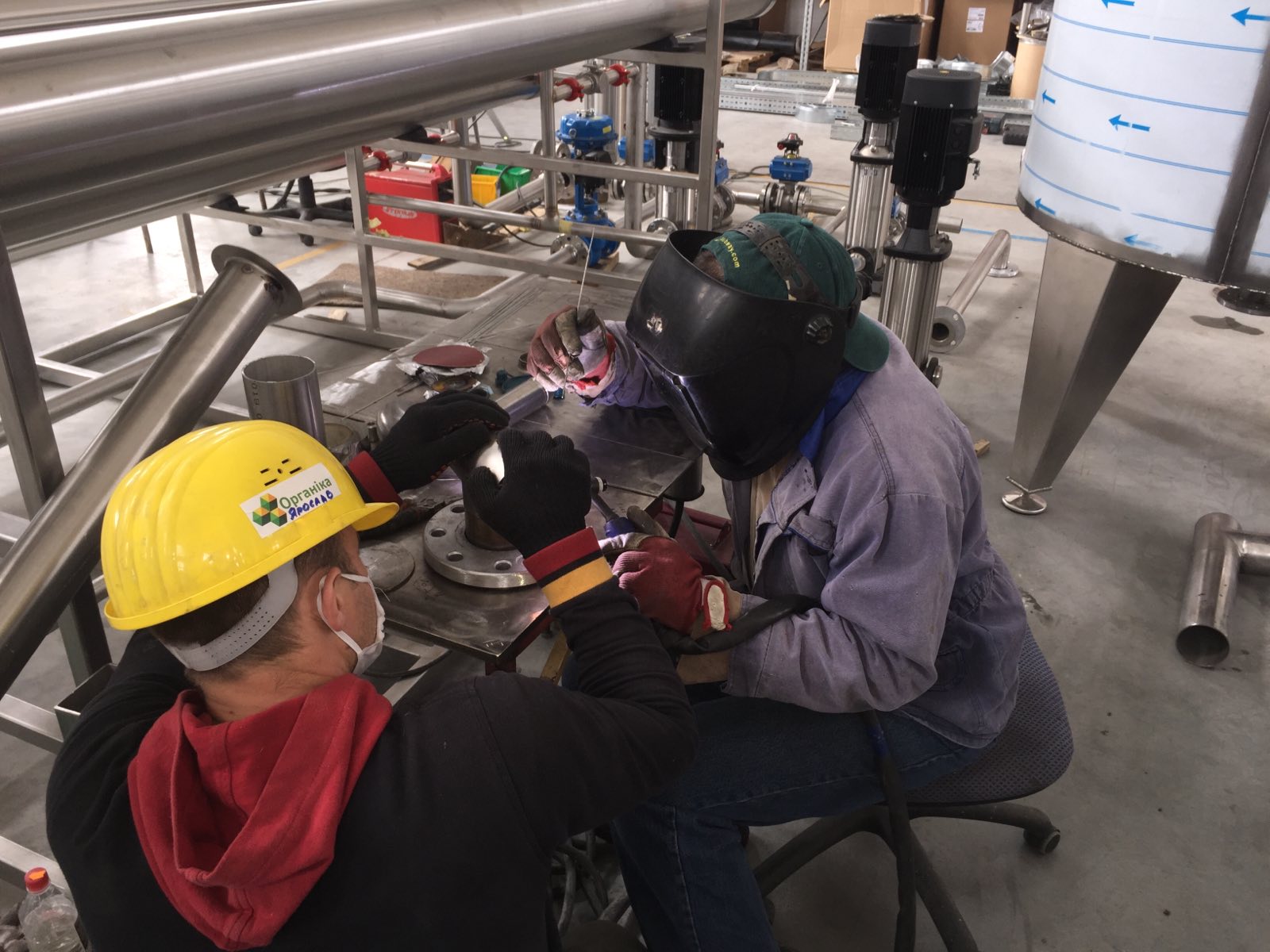

Engineers, welders, electricians, IT specialists: they are among the best

But the main process equipment was created by projecting engineers of ORGANIKA. The complex was born in Ukraine and is currently undergoing certification in European institutions for compliance with EU standards with the right to bear the CE mark.

Just before your eyes, an impressive smart design is being born in a spacious, bright workshop. Pipelines, intertwining conductors, ceramics and polymers, parts, mechanisms, and many sensors.

All this comes to life in the hands of Ukrainian professionals. Engineers, welders, electricians, IT specialists: they are among the best.

"Treatment equipment line" is currently undergoing certification in European institutions for compliance with EU standards with the right to bear the CE mark

"Treatment equipment line" is currently undergoing certification in European institutions for compliance with EU standards with the right to bear the CE mark

The ORGANIKA's case demonstrates that mechanical engineering today is not just parts for export. This is a clever system of protection of the environment which even leading economies have a need of.

All this comes to life in the hands of Ukrainian professionals